- Pigment for Color Masterbatch/Plastic

- Pigment for Water Based Ink

- Pigment for Solvent Based Ink

- Pigment for Offset Ink

- Pigment for Textile Printing Ink/Paste

- Pigment for Industrial Paint

- Pigment for Powder Coatings

- Pigment for Road Marking Paint

- Pigment for Automotive Paint/Refinish

- Pigment for Decorative Paint

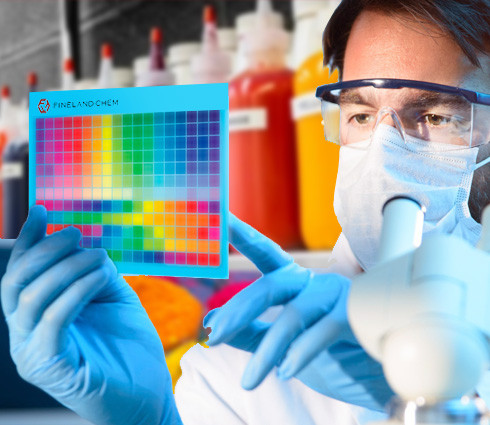

Pigment for Textile Printing Ink/Paste

Pigments used in textile printing ink/paste are specially formulated to adhere to fabric fibers and withstand various textile processing methods. Textile printing inks/pastes are applied to fabrics to create intricate designs, patterns, or solid colors. These pigments should exhibit good color fastness, durability, and resistance to washing and rubbing.

The four main methods of textile printing are block, roller, screen, and heat transfer printing. In each of these methods, the application of the color, usually as a thickened paste, is followed by fixation, usually by steaming or heating, and then removal of excess color by washing. Printing styles are classified as direct, discharge, or resist.

Disperse Dyes for Digital Transfer Printing:

1, Vibrant Colors: Disperse dyes are favored for their vivid and saturated colors, making them ideal for printing vibrant and colorful patterns in digital transfer printing.

2, High Dispersion Capability: Disperse dyes exhibit excellent dispersion, quickly dispersing in water to form a uniform dye solution. This feature ensures even absorption of the dye onto the fiber surface during the digital printing process.

3, Coverage on Fibers: Disperse dyes typically penetrate and cover fibers well, ensuring that printed patterns on the fabric surface appear clear and sharp.

4, High Stability: Disperse dyes demonstrate color stability post-printing, resisting fading from light, water, and washing. This ensures the durability and longevity of printed designs.

5, Rapid Coloring: Disperse dyes offer fast coloring, a crucial factor for efficient production in the digital printing process.

- How Choose

- Customization

- Specification Table

- Why Choose

- Related Products

Color characteristics

Choose a color that matches the desired printing effect.

Heat resistance

Different process the steaming temperature and time are different, it is important to choose the right product that will satisfy heat resistance.

Particle size

Particle size should be small and even.

Environmental friendliness

Choose environmentally friendly pigments that comply with relevant environmental regulations and standards.

Adaptability

Ensure that pigments are compatible with the printing equipment and paper used.

Adaptability

Adaptability- √

Excellent fluidity, wettability and adhesion: Fineland pigments can quickly adhere to the printing medium during the printing process and maintain stable color and performance.

- √

Uniformity and appropriate permeability: Fineland pigments have strong uniformity and appropriate permeability of textile printing.

Customization

Customization√ Provide small quantity customization services: If customers need small-scale production or rapid debugging of new products, we can provide small batch pigment customization services to help them obtain the required color samples in a short time.

- √

Customized solutions for different application areas: We can provide customized textile printing pigments tailored to the specific needs of our customers' different textiles.

Technical Support

Technical Support- √

Provide textile printing process optimization suggestions: Based on customers' textile printing equipment and processes, we can provide corresponding technical support to help them optimize printing effects and production efficiency. Ensuring that they can fully leverage the advantages of pigments.

Color |

Product Name

|

Color Index

|

PH

Value

|

Oil

absor

ption

|

Heat

℃

|

Light fast ness

|

Acid resis tance

|

Alkali resis tance

| TDS |

MSDS

|

|

Fast Yellow G | P.Y.3 | 6.0-7.0 | 35-45 | 160 | 5-6 | 5 | 4-5 | ||||

Briliant Yellow 5GX | P.Y.74 | 6.0-8.0 | 35-45 | 160 | 7 | 4 | 4 | ||||

Permanent Yellow | P.Y.12 | 6.0-7.0 | 45-55 | 180 | 5 | 5 | 4-5 | ||||

Diarylide Yellow AAOT | P.Y.14 | 6.0-7.0 | 40-50 | 180 | 5-6 | 5 | 4 | ||||

Permanent Yellow HR | P.Y.83 | 6.0-7.0 | 40-50 | 200 | 6-7 | 5 | 5 | ||||

Permanent Orange G | P.O.13 | 6.0-7.0 | 40-50 | 180 | 4-5 | 5 | 5 | ||||

Permanent Orange RL | P.O.34 | 6.0-7.0 | 45-55 | 200 | 5-6 | 5 | 5 | ||||

Permanent Red FRR | P.R.2 | 6.0-7.0 | 40-50 | 180 | 5 | 1-2 | 3-4 | ||||

Naphthol Red | P.R.22 | 6.0-7.5 | 40-50 | 120 | 5 | 5 | 4 | ||||

Permanent Red FR | P.R.21 | 6.0-7.5 | 40-50 | 120 | 4 | 5 | 4 | ||||

Permanent Red F4R | P.R.8 | 6.0-7.5 | 40-50 | 120 | 5 | 1-2 | 3-4 | ||||

Naphthol Red | P.R.170 | 6.0-7.0 | 45-55 | 230 | 7 | 5 | 5 | ||||

Manganese Red 2B Toner | P.R.48:4 | 6.0-7.5 | 45-55 | 200 | 7 | 4 | 5 | ||||

Naphthol Red 31 | P.R.31 | 6.0-7.0 | 40-50 | 150 | 7 | 5 | 5 | ||||

Permanent Red FGR | P.R.112 | 5.0-7.0 | 40-50 | 160 | 7 | 5 | 5 | ||||

Color |

Product Name

|

Color Index

|

PH

Value

|

Oil

absor

ption

|

Heat

℃

|

Light fast ness

|

Acid resis tance

|

Alkali resis tance

| TDS |

MSDS

|

|

DPP Red | P.R.254 | 6.0-7.5 | 45-55 | 280 | 7-8 | 5 | 5 | ||||

Quinacridone Magenta | P.R.122 | 6.0-7.0 | 45-55 | 270 | 7-8 | 5 | 5 | ||||

Permanent Carmine FBB | P.R.146 | 5.0-7.0 | 50-60 | 250 | 7 | 5 | 5 | ||||

Phthalocyanine Blue β form | P.B.15:3 | 6.0-7.5 | 40-50 | 280 | 7-8 | 5 | 5 | ||||

Phthalocyanine Blue α form | P.B.15:0 | 6.0-7.5 | 40-50 | 280 | 7-8 | 5 | 5 | ||||

Carbazol Violet | P.V.23 | 6.0-7.0 | 50-60 | 270 | 7-8 | 5 | 5 | ||||

Phthalocyanine Green 7 | P.G.7 | 6.0-8.0 | 60 | 220 | 7-8 | 5 | 5 | ||||

|

FL

|

Contains formaldehyde,excellent brightness and color strength |

|||||||||

|

FM

|

Contains formaldehyde,bright color,good thermal stability,great migration resistance |

|||||||||

FH | Contains formaldehyde,excellent color strength,great migration resistance,bright color,good thermal stability | |||||||||

FFL | Formaldehyde free,low cost,excellent performance in pigmentation,equality, brightness and vividness | |||||||||

FFH1 | Formaldehyde free,excellent brightness,good heatstability | |||||||||

FFH2 | Formaldehyde free,excellent brightness and colour strength | |||||||||

|

|

|

|

|

|||||||

Lemon yellow | Yellow | Orange yellow | Orange | Orange red | Pink | Cerise | Red | Magenta | Blue | Violet |

- Fineland will try best to fully understand your pigment needs and concerns, providing targeted suggestions and information. Our sales team has relevant product knowledge with excellent service. Welcome to inquire from us! Contact us, find your reliable pigment supplier!

- contact us

| Image | Pigment for Textile Printing Ink/Paste | Description | MOQ | More |

|---|---|---|---|---|

| Red-Pigment Red 22-Naphthol Red for textile printing and ink | Pigment Red 22, yellowish red, mainly recommend for paint, ink and fabric printing. | 1 | |

| Red-Pigment red 8-Permanent Red F4R For textile and ink | Pigment Red 8, pure bluish red, mainly recommend for water based printing inks and fabric printing. | 1 | |

| Red-Pigment Red 2-Permanent Red FRR for textile and ink | Pigment red 2, common red pigment, can be used for ink and textile printing. | 1 | |

| Orange-Pigment Orange 34-Permanent Orange RL 70 For Plastic, Paint and Ink | PO34, common orange pigment, pure yellowish orange, can be used for textile printing. | 1 | |

| Violet-Pigment Violet 23-Carbazol Violet-For Plastic, Paint and Ink | Pigment Violet 23, bluish violet with high color strength, mainly recommend for paint, plastic and printing ink. | 1 | |

| Red-Pigment Red 146-Naphthol Carmine FBB For Pinting ink/Textile | PR146 for textile printing ink, water based/ solvent based ink, also suitable for emulsion paint and architectural paint. | 1 | |

| RED-Pigment Red 31-Naphthol Red 31-For plastic, ink and textile printing | Pigment Red 31, bluish red, mainly recommend for printing ink, textile printing and rubber. | 1 | |

| Red-Pigment Red 21-Permanent Red FR-For paint and textile printing | Pigment Red 21 mainly recommend for paint and fabric printing. | 1 |

Consult Your Pigment Manufacturer

One of leading pigment manufacturers in China. We provide one-stop pigment solution, Make Sure high-quality and valuable pigment on time and on budget.

- *Name

- *Tel

- *Title

- *Content