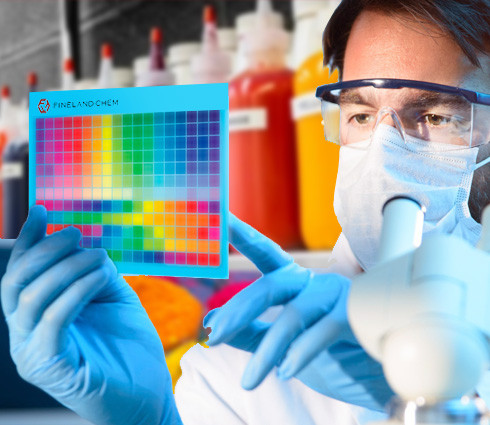

- Pigment for Color Masterbatch/Plastic

- Pigment for Water Based Ink

- Pigment for Solvent Based Ink

- Pigment for Offset Ink

- Pigment for Textile Printing Ink/Paste

- Pigment for Industrial Paint

- Pigment for Powder Coatings

- Pigment for Road Marking Paint

- Pigment for Automotive Paint/Refinish

- Pigment for Decorative Paint

Pigment for Solvent Based Ink

Solvent-based ink is made of solvents, resin, the connecting material, pigment and additives. It’s widely used for flexographic, gravure, screen printing and UV printing etc. Solvents mainly include alcohols, esters, benzenes, and ketones etc.The main connecting materials include resins like PA (polyamide/nylon), PAA (polyacrylic acid), NC (nitrocellulose), PU (polyurethane), CPP (chlorinated polypropylene) etc. Solvent based inks are mainly divided into two categories: surface printing and inner printing inks. As the name suggests, printing on the surface and printing on the inside. Both categories are different in printing processes,abrasiveness, the using of solvents, resins and additives etc.

In addition, surface printing ink has higher request on abrasiveness but with faster print speed. Its main solvents are dimethylbenzene and isopropanol; And important connecting materials are resins like PA (polyamide/nylon) and PAA (polyacrylic acid), which make the ink with good adhesion and brilliant gloss, but not applicable under high-temperature conditions. Inner printing ink mainly use toluene and ethyl acetate as the solvents. And its main resins are CPP (chlorinated polypropylene), NC (nitrocellulose), VC/VAC (vinyl chloride vinyl acetate copolymer) etc. For high-temperature or boiling-resistance inner printing ink, acetone and ethyl acetate are the main solvents.

- How Choose

- Customization

- Specification Table

- Why Choose

- Related Products

Color

Choose a color that matches the desired printing effect. There are various colors for you to choose from.

Compatibility

Ensure that the pigment matches the printing equipment and connecting resin used, thereby enabling better dispersion of pigments in the ink systems, ensuring good fluidity/viscosity and storage stability of inks.

Transparency and Hiding power

Transparency of pigment refers to degree of light transmission of the ink film formed after pigments formulated into ink and printed on paper or other materials. Hiding power is the covering power of the pigment to the underlying layer.

Solubility

Organic Pigments is soluble in some extent in inks, especially in the inks made of solvents with strong solubility. So this kind of inks usually require highly on Acid resistance, Alkali resistance, Alcohol resistance, Ester resistance, Benzene resistance and Ketone resistance.

Environmental friendliness

Choose environmentally friendly pigments that comply with relevant environmental regulations and standards.

Color Stability

Color Stability- √

Persistence: The color stability of powder coating pigments is very important, especially in long-term use and exposure to external environmental conditions. Fineland Pigment is resistant to factors such as light, heat, humidity, and chemical corrosion to ensure that the color does not fade or migrate.

Customization

Customization√ Specific color requirements: Some applications require very specific colors that cannot be achieved through standard pigments. In this case, Fineland pigment can provide customized pigments to meet these needs, ensuring that the colors fully meet the design or brand requirements.

- √

Accurate color matching: Fineland customized pigments achieve precise color matching to meet customer requirements. This is particularly important for high-end consumer goods, automotive coatings, and product design.

Technical Support

Technical Support- √

Provide color matching solutions: Based on the customer's resin system and process, Fineland provide corresponding technical support to help customer optimize the use of color masterbatch effects and production efficiency.

√ Training & guidance: Fineland provide guidance to enable the customer's production team can master the skills and key points of using masterbatch pigments, ensuring that they can fully leverage the advantages of pigments.

Color |

Product Name

|

Color Index

|

Density[g/cm 3 ]

|

Oil Absorption

|

AcidResistance

|

AlkaliResistance

|

Alcohol Resistance

|

Ester Resistance

| TDS |

MSDS

|

|

Benzidine Yellow G | P.Y.12 | 1.5 | 40-50 | 5 | 5 | 5 | 5 | ||||

Permanent Yellow GR | P.Y.13 | 1.5 | 35-45 | 5 | 5 | 5 | 4 | ||||

Permanent Yellow 2GS | P.Y.14 | 1.6 | 35-45 | 5 | 5 | 5 | 4 | ||||

Permanent Yellow HR | P.Y.83 | 1.7 | 35-45 | 5 | 5 | 5 | 5 | ||||

Permanent Orange G | P.O.13 | 1.6 | 35-45 | 4-5 | 4-5 | 4-5 | 4 | ||||

Permanent Orange RL | P.O.34 | 1.6 | 40-50 | 5 | 5 | 5 | 4 | ||||

Permanent Carmine FBB | P.R.146 | 1.7 | 40-50 | 5 | 5 | 5 | 4 | ||||

Fast Scarlet BBN | P.R.48:1 | 1.8 | 35-45 | 4 | 5 | 5 | 4 | ||||

Bronze Red C | P.R.53:1 | 1.8 | 40-50 | 4 | 4 | 4 | 4 | ||||

Fast Brilliant Red BBC | P.R.48:2 | 1.8 | 45-55 | 5 | 4 | 5 | 5 | ||||

Lithol Rubine 6B | P.R.57:1 | 1.7 | 45-55 | 4 | 4 | 4 | 5 | ||||

Rhdamine 6G | P.R.81 | 1.8 | 45-55 | 4 | 4 | 4 | 4 | ||||

Fast Violet Toner | P.V.3 | 1.8 | 40-50 | 5 | 5 | 5 | 4 | ||||

Phthalo Blue BGS | P.B.15:4 | 1.8 | 35-45 | 5 | 5 | 5 | 5 | ||||

Color |

Product Name

|

Color Index

|

Density[g/cm 3 ]

|

Oil Absorption

|

AcidResistance

|

AlkaliResistance

|

Alcohol Resistance

|

Ester Resistance

| TDS |

MSDS

|

|

Quindo Red | P.R.122 | 1.6 | 40-50 | 5 | 5 | 5 | 5 | ||||

Carbazol Violet | P.V.23 | 1.8 | 40-50 | 5 | 5 | 5 | 5 | ||||

|

FL

|

Contains formaldehyde,excellent brightness and color strength |

|||||||||

|

FM

|

Contains formaldehyde,bright color,good thermal stability,great migration resistance |

|||||||||

FH | Contains formaldehyde,excellent color strength,great migration resistance,bright color,good thermal stability | |||||||||

FFL | Formaldehyde free,low cost,excellent performance in pigmentation,equality, brightness and vividness | |||||||||

FFH1 | Formaldehyde free,excellent brightness,good heatstability | |||||||||

FFH2 | Formaldehyde free,excellent brightness and colour strength | |||||||||

|

|

|

|

|

|||||||

Lemon yellow | Yellow | Orange yellow | Orange | Orange red | Pink | Cerise | Red | Magenta | Blue | Violet |

|

Product Name

|

Color Index

|

Specification

|

Average Prime Particle Size[n/m]

|

BET surface are[m²/g]

|

Oil Absorption[ml/100g]

|

Volatile[100%]

|

PH Value

| TDS |

MSDS

|

FINE BLACK376 | P.B.7 | Powder | 34 | 83 | 98 | 1.5 | 7.9 | ||

FINE BLACK377 | P.B.7 | Powder | 30 | 60 | 48 | 1.5 | 9 | ||

FINE BLACK641 | P.B.7 | Powder | 50 | 42 | 50 | 4 | 3.5 | ||

FINE BLACK642 | P.B.7 | Powder | 25 | 100 | 62 | 5 | 2.5 |

Fineland is pigment manufacture approved by ISO9001, with a systematic and strict quality inspection and control system, providing clients with high-quality and stable products and supply services.

- Fineland will try best to fully understand your pigment needs and concerns, providing targeted suggestions and information. Our sales team has relevant product knowledge with excellent service. Welcome to inquire from us! Contact us, find your reliable pigment supplier!

- contact us

| Image | Pigment for Solvent Based Ink | Description | MOQ | More |

|---|---|---|---|---|

| RED-Pigment red 53:1-Red Lake C For plastic, ink | Pigment Red 53:1, golden red color, mainly recommend for plastic and water/solvent based ink. | 1 | |

| Red-Pigment Red 48:2-Calcium Red 2B For plastic and ink | Pigment Red 48:2, common red pigment, mainly recommend for plastic and solvent based ink. | 1 | |

| Red-Pigment Red 48:1-Permanent Red BB For plastic, ink and paint | PR48:1, barium salt lake pigment, can be used for gravure solvent based ink. | 1 | |

| Orange- Pigment Orange 13-Permanent Orange For plastic, paint and ink | PO13, common orange pigment, can be used for paint, ink and plastic. | 1 | |

| Orange-Pigment Orange 5-Permanent Orange 2G For Paint and Printing Ink | PO5, one of the important orange color. High covering and weather resistance, it's good for paint and solvent based ink. | 1 | |

| Violet-Pigment Violet 3-Methyl Violet(PTMA) For Printing Ink | Pigment Violet 3, strong bluish violet color, mainly recommend for printing ink. | 1 | |

| Violet-Pigment Violet 23-Carbazol Violet-For Plastic, Paint and Ink | Pigment Violet 23, bluish violet with high color strength, mainly recommend for paint, plastic and printing ink. | 1 | |

| Yellow-Pigment Yellow 13-Diarylide Yellow AAMX-For printing ink | Pigment Yellow 13, common yellow pigment, mainly for plastic and printing ink. | 1 | |

| Yellow-Pigment yellow 14-Diarylide Yellow AAOT for solvent based ink | Pigment Yellow 14, common greenish yellow pigment, can be used for plastic and water/solvent based ink. | 1 | |

| Yellow-Pigment Yellow 83-Diarylide Yellow HR For Plastic, Paint and Ink | Pigment Yellow 83, common pigment, more reddish than yellow 13, is well used in different ink systems. | 1 |

Consult Your Pigment Manufacturer

One of leading pigment manufacturers in China. We provide one-stop pigment solution, Make Sure high-quality and valuable pigment on time and on budget.

- *Name

- *Tel

- *Title

- *Content