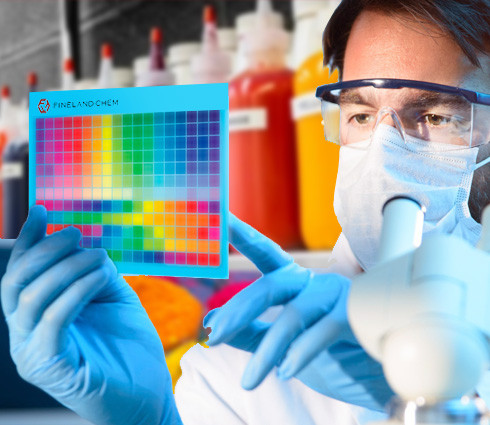

- Pigment for Color Masterbatch/Plastic

- Pigment for Water Based Ink

- Pigment for Solvent Based Ink

- Pigment for Offset Ink

- Pigment for Textile Printing Ink/Paste

- Pigment for Industrial Paint

- Pigment for Powder Coatings

- Pigment for Road Marking Paint

- Pigment for Automotive Paint/Refinish

- Pigment for Decorative Paint

Pigment for Color Masterbatch/Plastic

Plastic is composed of synthetic polymers, and its plasticity and processability have made it widely used in many different fields. Plastic products have various characteristics, such as durability, lightweight, insulation performance, etc., making them suitable for various purposes.

Plastic masterbatch is pigment particle that used for coloring plastic product. It's pre mixed with pigments and plastic substrates to form granules. Can be fully mixed with plastic raw materials through processes like mixing, extrusion, and injection molding to evenly disperse the color.

In daily industrial production, the use of color masterbatches is convenient and easy, uniformity and stability, environmental protection and cost saving, which is more widespread than directly using pigment powder to color plastics. The following is mainly an introduction to color masterbatch pigments.

- How Choose

- Customization

- Specification Table

- Why Choose

- Related Products

Color characteristics

Consider hue, brightness, saturation, strength and any special color requirements. Ensure that the selected pigment can achieve the desired color effect.

Material compatibility

Consider the compatibility between the pigment and carrier material . Ensure the pigment can be evenly dispersed without causing instability or separation.

Cost factor

Consider the procurement and preparation costs of pigments to ensure the selection of appropriate pigments within the budget.

Quality and supply reliability

Choose reliable pigment suppliers, establish stable cooperative relationships, and ensure the quality and supply reliability of pigments.

Color stability

Different pigments may exhibit a trend of color fading or bleeding due to different environmental conditions such as temperature and climate. Choose pigments with good color stability to ensure consistency in color during long-term use.

Stability

Stability- √

Persistence: The color stability of color masterbatch pigments is crucial, especially in long-term use and exposure to external environmental conditions. Fineland Pigment is resistant to factors such as light, heat, humidity, and chemical corrosion to ensure that the color does not fade or migrate.

- √

Maintaining consistency: Fineland Pigment has consistent color, whether prepared in batches at different times or in different products, the color is always consistent.

Customization

Customization√ Specific color requirements: Some applications require very specific colors that cannot be achieved through standard pigments. In this case, Fineland pigment can provide customized pigments to meet these needs, ensuring that the colors fully meet the design or brand requirements.

- √

Accurate color matching: Fineland customized pigments achieve precise color matching to meet customer requirements. This is particularly important for high-end consumer goods, automotive coatings, and product design.

- √

Innovation and differentiation: By customizing pigments, Fineland can bring speciality and differentiation to customer’s products, making them stand out in market competition.

Technical Support

Technical Support- √

Provide color matching solutions: Based on the customer's resin system and process, Fineland provide corresponding technical support to help customer optimize the use of color masterbatch effects and production efficiency.

√ Training & guidance: Fineland provide guidance to enable the customer's production team can master the skills and key points of using masterbatch pigments, ensuring that they can fully leverage the advantages of pigments.

Color |

Product Name

|

Color Index

|

Stability | Application | TDS |

MSDS

|

|||||

Tint shade | Weather resistance(1-8 points) | To temperature℃ | Migration resistance(1-5 points) | PP | PE | PVC |

|||||

Permanent Yellow 2GS | P.Y.14 | 5 | 200 | 4 | ● | ● | ● | ||||

Permanent Yellow GG | P.Y.17 | 5 | 220 | 4-5 | ● | ● | ● | ||||

Benzidine Yellow G | P.Y.12 | 4 | 180 | 3 | 〇 | 〇 | 〇 | ||||

Permanent Yellow GR | P.Y.13 | 5-6 | 220 | 4-5 | ● | ● | ● | ||||

Permanent Yellow HR | P.Y.83 | 6-7 | 220 | 5 | ● | ● | ● | ||||

Permanent Orange G | P.O.13 | 5 | 180 | 4 | 〇 | 〇 | 〇 | ||||

Permanent Orange RL | P.O. 34 | 6-7 | 200 | 3 | ● | 〇 | 〇 | ||||

Bronze Red C | P.R.53:1 | 8 | 4 | 2-3 | ● | 〇 | 〇 | ||||

Fast Red 2BSP | P.R.48:3 | 6 | 200 | 4 | ● | ● | ● | ||||

Fast Scarlet BBN | P.R.48:1 | 4-5 | 200-240 | 2-3 | ● | 〇 | ● | ||||

Fast Brilliant Red 2BP | P.R.48:2 | 6 | 230 | 4 | ● | ● | ● | ||||

Lithol Rubine 4BP | P.R.57:1 | 7 | 220 | 3-4 | ● | ● | ● | ||||

Phthalocyan ine Blue BS | P.B.15:1 | 8 | 230 | 5 | 〇 | ● | ● | ||||

Color |

Product Name

|

Color Index

|

Stability | Application | TDS |

MSDS

|

|||||

Tint shade | Weather resistance(1-8 points) | To temperature℃ | Migration resistance(1-5 points) | PP | PE | PVC |

|||||

Pigment Yellow 81 | P.Y.81 | 7-8 | 260 | 3 | ● | ● | ● | ||||

Monoazo Yellow WGP | P.Y.168 | 7-8 | 240-260 | 3-4 | ● | 〇 | ● | ||||

Pigment Yellow 62 | P.Y.62 | 7 | 260 | 3-4 | ● | ● | ● | ||||

Fast Yellow HGR | P.Y.191 | 8 | 300 | 4-5 | ● | ● | ● | ||||

Monoazo Yellow HRP | P.Y.183 | 8 | 300 | 4-5 | ● | ● | ● | ||||

Benzimidazo lone Orange | P.O.64 | 7-8 | 300 | 4-5 | ● | ● | ● | ||||

Benzimidazo lone Orange | P.O.36 | 8 | 280 | 4 | ● | ● | ● | ||||

DPP Red BO | P.R.254 | 8 | 300 | 4-5 | ● | ● | ● | ||||

Quindo Red 122 | P.R.122 | 8 | 280 | 4-5 | ● | ● | ● | ||||

Phthalocyan ine Green | P.G.7 | 8 | 300 | 5 | ● | ● | 〇 | ||||

Phthalocyan ine Blue BGS | P.B.15:3 | 8 | 280 | 5 | ● | ● | 〇 | ||||

Indanthrone Blue | P.B.60 | 8 | 350 | 5 | ● | ● | 〇 | ||||

Permanent Violet RL | P.V.23 | 8 | 280 | 4-5 | ● | ● | 〇 | ||||

|

FL

|

Contains formaldehyde,excellent brightness and color strength |

|||||||||

|

FM

|

Contains formaldehyde,bright color,good thermal stability,great migration resistance |

|||||||||

FH | Contains formaldehyde,excellent color strength,great migration resistance,bright color,good thermal stability | |||||||||

FFL | Formaldehyde free,low cost,excellent performance in pigmentation,equality, brightness and vividness | |||||||||

FFH1 | Formaldehyde free,excellent brightness,good heatstability | |||||||||

FFH2 | Formaldehyde free,excellent brightness and colour strength | |||||||||

|

|

|

|

|

|||||||

Lemon yellow | Yellow | Orange yellow | Orange | Orange red | Pink | Cerise | Red | Magenta | Blue | Violet |

|

Product Name

|

Color Index |

Specification

|

Average Prime Particle Size | BET surface area | Oil Absorption | Volatile | PH value | Application | TDS |

MSDS

|

||

PP | PE | PVC |

||||||||||

FINEBLACK 8180 | P.B.7 | Powder | 20 | 185 | 62 | 1.5 | 7.5 | ● | ● | ● | ||

FINEBLACK 8181 | P.B.7 | Powder | 21 | 170 | 60 | 1.8 | 7.8 | ● | ● | ● | ||

FINEBLACK 8182 | P.B.7 | Powder | 30 | 80 | 72 | 1.5 | 8.5 | ● | ● | ● | ||

FINE BLACK2101 | P.B.7 | Powder | 24 | 155 | 54 | 2 | 7.7 | ● | ● | ● | ||

FINE BLACK490 | P.B.7 | Powder | 31 | 90 | 79 | 1.5 | 8 | ● | ● | |||

Color |

Product Name

|

Color Index

|

Light Fastness (1-8 degree) | Heat Resistance (° C)Application |

TDS

|

MSDS | ||||

Full shade | Tint shade | PS | PMMA | PC | PA 6 |

|||||

Fluorescent Yellow 8G | S.G.5 | 5-6 | 300 | 300 | 300 | 280 | ||||

● | ● | ● | ● | |||||||

Fluorescent Yellow 3G | S.Y.98 | 6-7 | 300 | 300 | 300 | 280 | ||||

● | ● | ● | ● | |||||||

Transparent Yellow YC | S.Y.33 | 7-8 | 300 | 300 | 300 | 260 | ||||

● | ● | ● | 〇 | |||||||

Transparent Yellow 3G | S.Y.93 | 8 | 300 | 300 | 340 | / | ||||

● | ● | ● | / | |||||||

Transparent Yellow G | S.Y.114 | 8 | 300 | 300 | 340 | / | ||||

● | ● | ● | / | |||||||

Transparent Orange 3G | S.O.60 | 8 | 300 | 300 | 350 | 300 | ||||

● | ● | ● | ● | |||||||

Fluorescent Red GG | S.O.63 | 6-7 | 300 | 300 | 300 | 280 | ||||

● | ● | ● | ● | |||||||

Fluorescent Red 5B | V.R.41 | 4 | 300 | 300 | 300 | / | ||||

● | ● | ● | / | |||||||

Transparent Red EG | S.R.135 | 8 | 300 | 300 | 350 | 260 | ||||

● | ● | ● | ● | |||||||

Transparent Red E2G | S.R.179 | 8 | 300 | 300 | 350 | 300 | ||||

● | ● | ● | ● | |||||||

Transparent Red 454 | S.R.195 | 8 | 280 | 260 | 300 | / | ||||

● | ● | ● | / | |||||||

Transparent Violet R | S.V.59 | 6-7 | 300 | 300 | 300 | / | ||||

● | ● | ● | / | |||||||

Transparent Green 5B | S.G.3 | 7-8 | 300 | 300 | 350 | 280 | ||||

● | ● | ● | ● | |||||||

Transparent Blue 2N | S.B.35 | 6-7 | 280 | 300 | 300 | / | ||||

● | ● | ● | / | |||||||

Transparent Blue 2B | S.B.104 | 7-8 | 300 | 300 | 340 | 280 | ||||

● | ● | ● | ● | |||||||

Transparent Violet B | S.V.13 | 7 | 300 | 300 | 350 | / | ||||

● | ● | ● | / | |||||||

- Fineland will try best to fully understand your pigment needs and concerns, providing targeted suggestions and information. Our sales team has relevant product knowledge with excellent service. Welcome to inquire from us! Contact us, find your reliable pigment supplier!

- contact us

| Image | Pigment for Color Masterbatch/Plastic | Description | MOQ | More |

|---|---|---|---|---|

| Red-Pigment Red 149-Perylene Red BL For Plastic | Pigment Red 149, pure slightly bluish red color, recommend for plastic, in soft PVC has excellent migration resistance. | 1 | |

| Red-Pigment Red-P.R.57:1(Lithol Rubine) For plastic | Pigment Red57:1, Lithol Rubine red, most basic color, is widely used for plastic. | 1 | |

| Yellow-Pigment yellow 191-PV Fast Yellow HGR For plastic | Pigment Yellow 191, color shade similar with PY83, mainly recommend for plastic. | 1 | |

| Yellow-Pigment Yellow 183 For plastic | Pigment Yellow 183, reddish yellow pigment, mainly recommend for plastic. | 1 | |

| Yellow-Pigment Yellow 180-Benzimidazolone Yellow HG For Plastic | Pigment Yellow 180, green tone yellow, mainly recommend for plastic. | 1 | |

| Yellow-Pigment Yellow 168-Irgalite Yellow K-5G For Plastic and paint | Pigment Yellow 168, slightly greenish tone yellow, mainly recommend for plastic. | 1 | |

| Yellow-Pigment Yellow 139-Isoindoline Yellow 139 For plastic, paint and ink | PY139, reddish yellow, excellent light and weather fastness, generally applied in plastic, paint and printing ink. | 1 | |

| Yellow-Pigment Yellow 110-Cromophtal Yellow 2RLT For Plastic and ink | Pigment Yellow 110, high performance pigment, strong reddish yellow, mainly recommend for plastic, paint and ink. | 1 | |

| Yellow-Pigment yellow 81-Diarylide Yellow H10G for plastic, paint and ink | Pigment Yellow 81, mainly recommend for plastic, printing inks, fabric printing paste and other coatings. | 1 | |

| Yellow-Pigment Yellow 62-Irgalite Yellow WSR for plastic | Pigment Yellow 62, hansa yellow lake pigment, mainly recommend for plastic. | 1 | |

| Yellow-Pigment Yellow 17-Diarylide Yellow AAOA for plastic | Pigment Yellow 17, common yellow pigment, mainly recommend for plastic, ink and textile printing paste. | 1 | |

| Yellow-Pigment Yellow 13-Diarylide Yellow AAMX-For plastic | Pigment Yellow 13, common yellow pigment, mainly for plastic and printing ink. | 1 |

Consult Your Pigment Manufacturer

One of leading pigment manufacturers in China. We provide one-stop pigment solution, Make Sure high-quality and valuable pigment on time and on budget.

- *Name

- *Tel

- *Title

- *Content